Aluminum alloy cables cannot be used as fire-resistant cables

- Categories:Common Problem

- Author:

- Origin:

- Time of issue:2021-12-13

- Views:0

(Summary description)In decorative building materials, we often see aluminum alloy cables. Aluminum alloy cables are energy-saving and environmentally friendly products made of aluminum alloy materials as conductors, using a unique roll-formed wire strand production process and annealing treatment.

Aluminum alloy cables cannot be used as fire-resistant cables

(Summary description)In decorative building materials, we often see aluminum alloy cables. Aluminum alloy cables are energy-saving and environmentally friendly products made of aluminum alloy materials as conductors, using a unique roll-formed wire strand production process and annealing treatment.

- Categories:Common Problem

- Author:

- Origin:

- Time of issue:2021-12-13

- Views:0

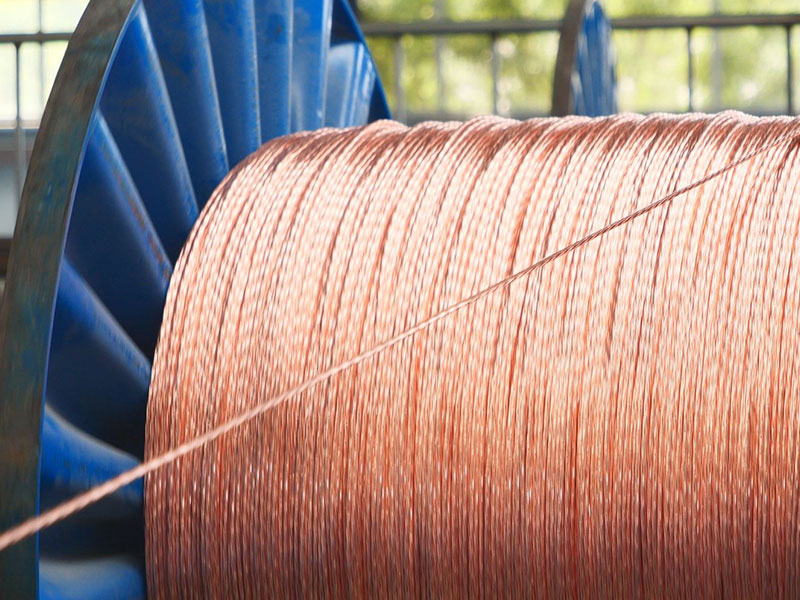

In decorative building materials, we often see aluminum alloy cables. Aluminum alloy cables are energy-saving and environmentally friendly products made of aluminum alloy materials as conductors, using a unique roll-formed wire strand production process and annealing treatment.

Aluminum alloy profile conductor not only maintains the excellent performance of pure aluminum, greatly improves the performance of mechanical equipment, but also solves the problems of low tensile strength, poor compressive strength, and poor compressive strength creep performance. The corrosion resistance and flexibility are poor, ensuring long-term stable operation of the cable. The introduction of wire aluminum alloy profiles is a major technological improvement in the raw materials of cables and wires, which has led to the reform of wire raw materials.

However, a key issue that everyone overlooks is the safety of cable connections. Everyone should understand that cable problems usually exist in cable connections. So, what is the safety factor of aluminum alloy cables? Next, I want Yu Shengxiang Wire and Cable to show you the connection safety of aluminum alloy cables.

Before mastering the connection safety factor of aluminum alloy cables, let's take a look at the actual situation. This is the large-scale application of aluminum alloy cables in steelmaking plants. After it was completed and put into production, it became popular twice a year, resulting in a shutdown of more than half a month and an immediate property loss of 200 million yuan. It can be seen from examples that the large-scale marketing and promotion of aluminum alloy cables in cities, factories and mines across the country has long left hidden safety hazards for large cities, factories and mines, and the safety factor of aluminum alloy cables is not very high. it is good.

So, what is the reason for the poor safety of aluminum alloy cable connections? This is because aluminum alloy cables have pure natural shortcomings in fire prevention and corrosion resistance, which are mainly reflected in the following aspects:

(1) Due to the addition of magnesium, copper, zinc and copper to the aluminum alloy cable, the heat treatment process is improved, which easily leads to uneven physical conditions. When there is ground stress and corrosive liquid, aluminum alloy cables will be broken, delaminated corrosion and stress corrosion, which are more easily corroded than aluminum cables.

(2) The high temperature resistance of aluminum alloy cables is much less than that of copper cables, which is mainly due to the determination of the raw materials of the wires. The melting point of copper is 1080°C, and the melting point of aluminum and aluminum alloys is 660°C. Therefore, when the melting point temperature of the aluminum alloy cable exceeds the melting point temperature or is in a fire accident area, the cable will melt in a very short time and lack electrical conductivity. Therefore, aluminum and aluminum alloy profiles are not suitable for use as fire-resistant cable conductors, nor for distribution networks and housing applications in factories and mining enterprises.

(3) Aluminum alloy profiles are made by adding special elements to ordinary aluminum, which can improve the creep properties of ordinary aluminum, but the horizontal correlation of ordinary aluminum is also very limited, which is very different from copper; Improving the creep resistance of aluminum alloy cables is closely related to the processing technology, technology and quality management level of each company. Therefore, if cable manufacturers want to better reduce costs, the creep resistance of aluminum alloy cables may be very low, resulting in fire accidents.

The above is a detailed introduction to the safety factor of aluminum alloy cable connection. Generally speaking, when connecting aluminum alloy cables, we should pay more attention to this problem to prevent serious danger to our own lives.

Scan the QR code to read on your phone

Recommended

Tel:

Add:

Luchan Street, Yongnian District, Handan city, Hebei Province

E-mali:

About Us

GUOZHI cold heading machine has always adhered to the "three heart" concept, so that customers buy convenient rest assured, practical peace of mind, after sale fast worry!

Leave a message

+86-18630165577

+86-18630165577

Message

Message